Biological tissues have highly complex and functional architectures. In order to construct engineered tissue with a high degree of complexity, cells must be provided with a suitable three dimensional synthetic or biological scaffolds upon which they can adhere and proliferate.

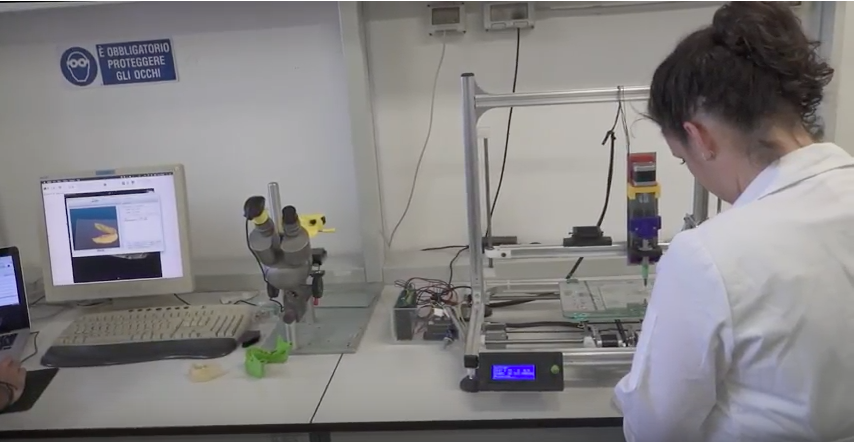

The Biofabrication Group aims at combining advanced fabrication technologies, including 3D printing, for creating scaffolds, in-vitro models, biosensors and actuators using smart and biomaterials. Applications are mainly focused on Tissue Engineering, regenerative medicine and biotechnologies.

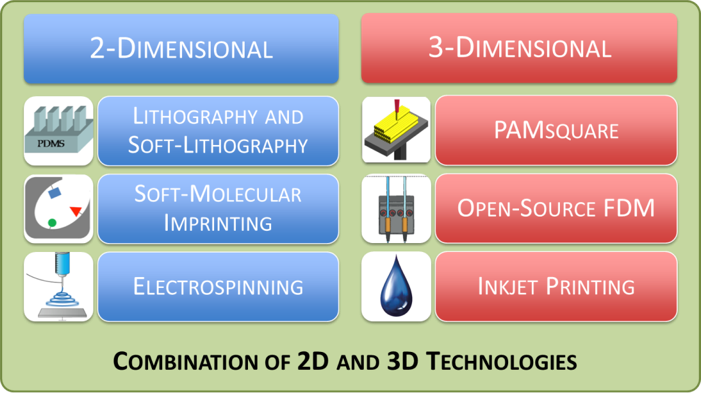

The integration of 2D and 3D technologies are essential for fabricating complex structures using different materials (including living cells) at different scales, from nanometers up to centimeters.

Between the different fabrication technologies, the group has strong expertise in

- Soft lithography, including the fabrication of microfluidic devices

- Soft-MI, a technology patented by the group for imprinting the shape of molecules and cells onto a substrate

- Electrospinning, for production of nanofibers matrices, with applications as scaffolds, but also fabrics, filters, and packaging

- Fused deposition modelling, from filaments and pellet

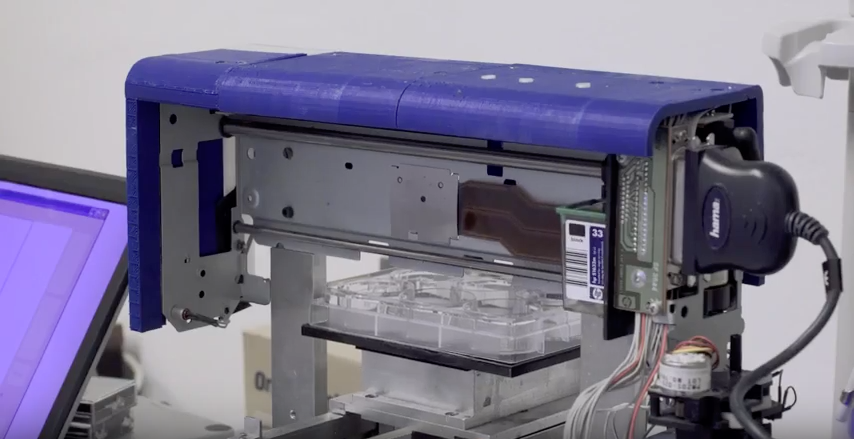

- Inkjet printing, for printing cells, nanoparticles and sensors

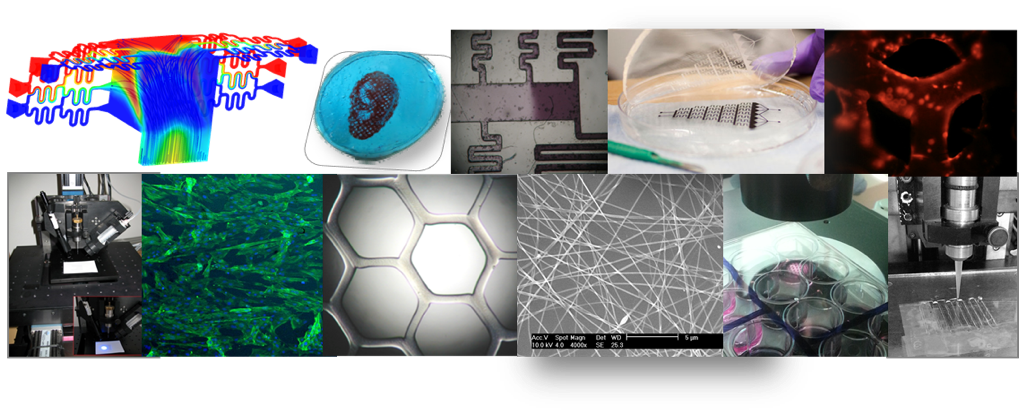

Simulation tools, including Finite Element Modelling and living cell metabolism mathematical models, and mechanical characterization are also part of the expertise of the group.

Contacts

Coordinator: Giovanni Vozzi

Team: Carmelo De Maria, Francesca Montemurro, Aurora De Acutis, Anna Lapomarda, Gabriele Fortunato, Francesco Biagini

Social media channel: Twitter @BioFabUnipi

Contact: g.vozzi@centropiaggio.unipi.it

Video: https://www.youtube.com/watch?v=adbCa1sxinU&t=10s

Some research Activities

- Printing of bio-molecules or cells using ink-jet system

- Smart scaffolds for monitoring cell process based on impedance characteristics

Current projects

- Biomembrane: Bioengineered in vitro model of retinal pigmented epithelium of human eye (Coordinator, M-ERA.NET EU Project)

- IMAGO:Gruppo di lavoro congiunto Italia Messico sulla Biofabbricazione per lo sviluppo di un sistema di Bioprinting multimateriale e multiscala per lo sviluppo di modelli 3D in vitro di tessuto muscolare. (Coordinator, Ministero degli Affari esteri e della cooperazione internazionale, AMEXIC)

- Kerapack: A novel integrated approach for the reduction, recycling and reuse of poultry feathers by keratins based packaging manufacturing. (Coordinator, MANUNET EU Project)

- GIOTTO: Active aGeIng and Osteoporosis: The next challenge for smarT nanobiOmaterials and 3D technologies (Partner - H2020 EU project GA 814410)

Flyer

Gallery